Tarmac Driveways Coventry - Installation & Resurfacing Specialists

INCLUDE YOUR MEASUREMENTS & EVEN A PHOTO FOR A QUICK PROVISIONAL TARMAC DRIVEWAY QUOTE

SEND ANYTIME 24/7

Driveways Coventry tarmac driveway quote

Professional Tarmac & Asphalt Driveway Services Across Coventry

Tarmac driveways make up a significant portion of the drives across Coventry, particularly in properties built from the 1960s onwards. If you've got one that's starting to show its age - cracks appearing, surface stones coming loose, or moss taking hold - you're probably weighing up whether to resurface or go for something completely different.

At DNA Driveways Coventry, we've been installing and resurfacing tarmac driveways across the area for over 15 years. We work with both traditional tarmac and modern asphalt surfaces, and we can give you honest advice about whether your existing drive can be saved with resurfacing or if it needs replacing entirely.

Tarmac remains one of the most cost-effective driveway options at £40-£60 per square metre for new installations, or £25-£40 per square metre for resurfacing. Installation is typically faster than block paving or resin, and modern asphalt surfaces are more durable and weather-resistant than older tarmac installations.

Whether you're looking to install a new tarmac driveway, resurface an existing one, or explore colour options beyond traditional black, we can help. We cover Coventry and surrounding areas including Kenilworth, Binley Woods, Allesley, and Leamington Spa.

Tarmac Driveways near me

If you're looking for a tarmac driveways near me in Coventry then please get in touch today

How Much Does a Tarmac Driveway Cost in Coventry?

Tarmac driveway costs in Coventry range from £60 per square metre for new installations, making it one of the most affordable driveway options available. Resurfacing an existing tarmac driveway costs from £40 per square metre - roughly half the price of full replacement.

Tarmac Driveway Pricing Breakdown:

- Standard black tarmac: £40-£50 per m²

- Asphalt (superior quality): £50-£60 per m²

- Coloured tarmac: £55-£65 per m² (red, buff, green options)

- Resurfacing only: £25-£40 per m²

- Tarmac with block paving edging: Add £15-£20 per linear metre

For an average 50m² driveway in Coventry, expect to pay £2,000-£3,000 for new installation or £1,250-£2,000 for resurfacing. Final costs depend on site access, existing surface removal, drainage requirements, and any edging or features.

Why Choose Tarmac for Your Coventry Driveway?

Tarmac and asphalt driveways offer several practical advantages that make them popular choices across Coventry, particularly for homeowners who want a straightforward, cost-effective solution.

Speed of Installation

Tarmac installations are typically faster than alternatives. Once the base is prepared, the surface can be laid in 1-2 days for most domestic driveways. The material arrives hot and needs laying promptly, which means the surface installation happens quickly once it starts.

You can use your driveway within 24 hours of installation for light vehicles - significantly faster than concrete which needs 7-10 days to cure. This makes tarmac suitable if you need to minimize disruption or can't park on the street for extended periods.

Cost Effectiveness

At £40-£60 per square metre, tarmac sits at the lower end of driveway costs. Only basic concrete competes on price, and tarmac provides a smoother, more refined finish than standard concrete.

The ability to resurface rather than replace offers further savings. If your existing tarmac base is sound but the surface has deteriorated, resurfacing at £25-£40 per square metre gives you what's effectively a new driveway for half the cost of replacement.

Durability & Weather Resistance

Modern asphalt surfaces handle British weather conditions well. The flexible nature of the material allows it to cope with temperature variations without cracking as concrete might. Properly installed and maintained tarmac driveways last 15-20 years, with resurfacing extending the life by another 10-15 years.

Asphalt (the modern alternative to traditional tarmac) offers superior resistance to fuel and oil spills compared to older tarmac formulations. This matters if you park vehicles that occasionally leak or if you do vehicle maintenance on your drive.

Low Initial Maintenance

New tarmac surfaces require minimal maintenance in their first few years. The smooth, sealed surface resists weed growth and doesn't have joints where vegetation can establish. Routine sweeping and occasional washing keeps the surface clean without specialist products or equipment.

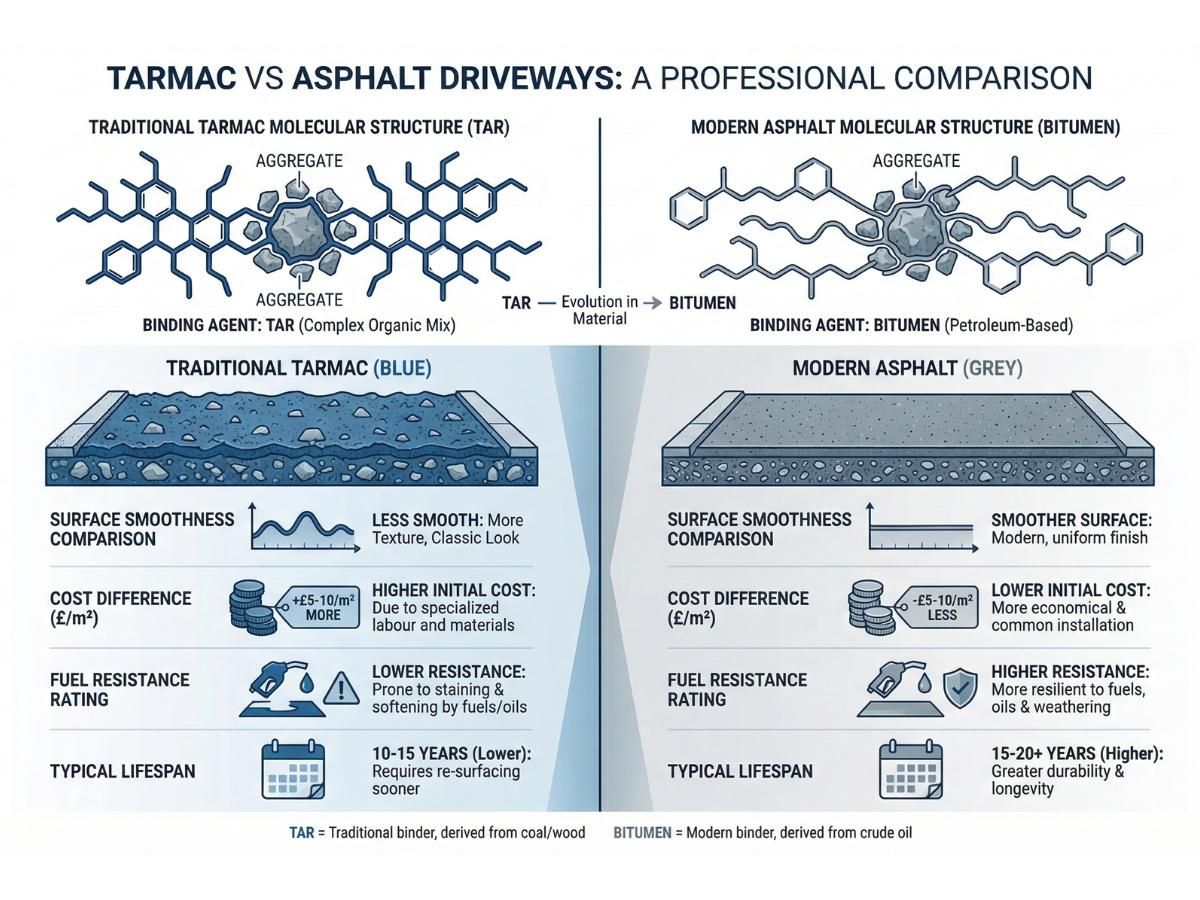

Tarmac vs Asphalt - Understanding the Difference

The terms get used interchangeably, but tarmac and asphalt are technically different materials. Understanding the distinction helps you make an informed choice about which suits your driveway.

What is Tarmac?

Tarmac - technically called tarmacadam - uses tar as its binding agent. Crushed stone aggregates get coated in tar, then laid and compacted to create the finished surface. This was the original method used for road surfacing from the early 1900s.

Traditional tarmac has largely been superseded by asphalt for new installations, though the term "tarmac driveway" persists in common usage. Older driveways installed before the 1990s are likely genuine tarmac.

What is Asphalt?

Asphalt uses bitumen (a petroleum by-product) as the binding agent instead of tar. The installation process is similar - aggregates get coated in hot bitumen, then laid and compacted - but the material properties differ.

Bitumen provides better adhesion than tar, creating a slightly smoother finish. Asphalt surfaces are more resistant to petrochemical damage (fuel and oil spills), weather better over time, and generally last longer than traditional tarmac.

Which Should You Choose?

For new installations, we use asphalt. It's the modern standard and offers better performance characteristics across the board. The cost difference is minimal - typically £5-10 per square metre more than traditional tarmac - and the improved longevity and resistance justify this.

When resurfacing existing tarmac driveways, we assess what's currently there and recommend the most suitable option. Asphalt can be laid over old tarmac bases, effectively upgrading your driveway to the better material.

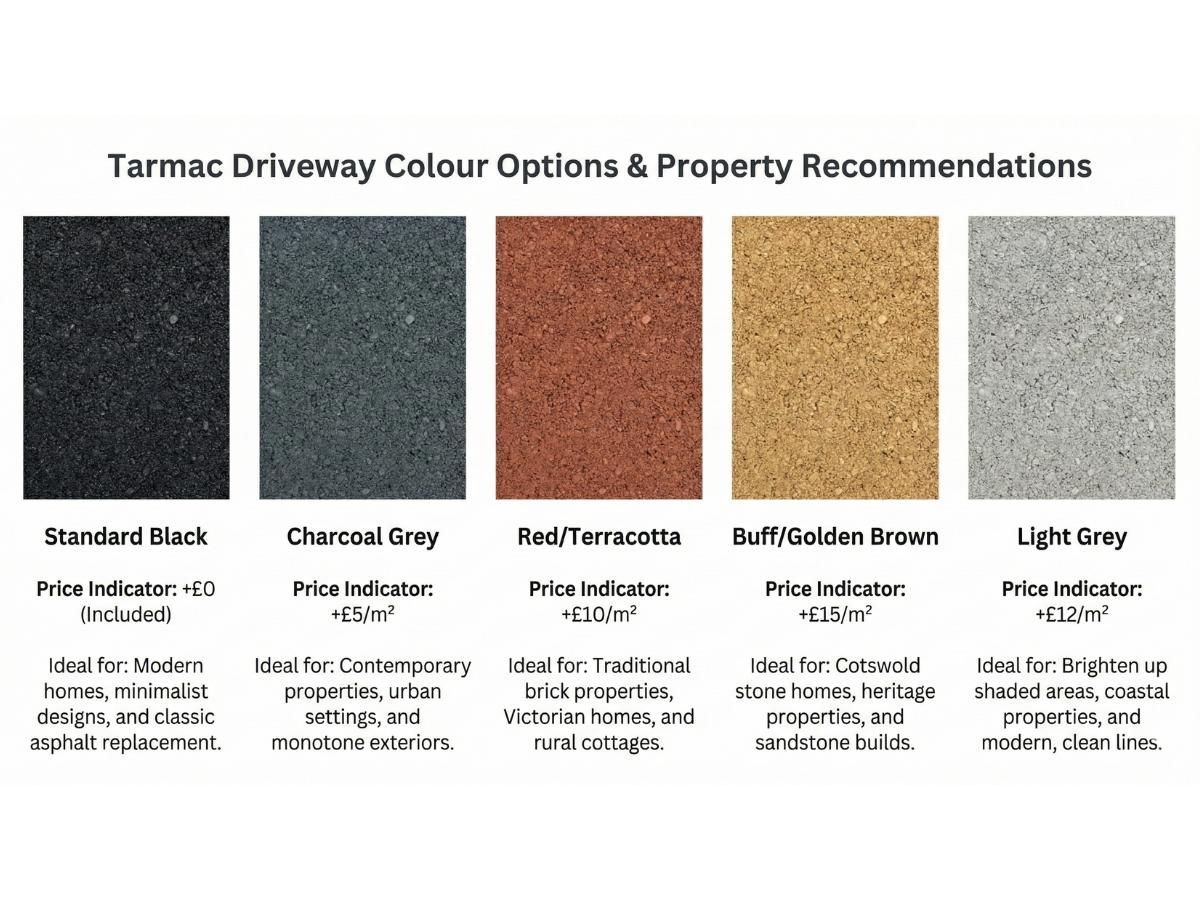

Colour Options

Both tarmac and asphalt are available in colours beyond standard black or charcoal. Popular options include:

- Red/Terracotta - Suits traditional brick properties

- Buff/Golden Brown - Complements Cotswold stone or sandstone

- Green - Blends with garden surroundings

- Light Grey - Contemporary appearance for modern properties

Coloured surfaces cost £10-15 per square metre more than standard black, but they create visual interest and can help your driveway complement your property's character rather than simply being a functional black surface.

Coloured Tarmac Drives

Tarmac Driveway Installation Process in Coventry

Understanding what happens during installation helps you plan around the work and know what to expect at each stage. Most tarmac installations take 3-5 days from start to finish.

Site Assessment & Preparation

We start by assessing your existing surface and ground conditions. If you're replacing an old driveway, we need to establish whether the existing base can be retained or needs complete removal.

Tarmac requires a solid, stable base - typically 150-200mm of compacted Type 1 MOT aggregate. If your existing base is sound (common with old tarmac or concrete driveways), we can potentially work over it, reducing excavation costs and installation time.

For new driveways on former garden areas, we excavate to the required depth, remove topsoil, and install the full base structure from scratch.

Excavation & Base Installation

Excavation involves removing existing surfaces and digging to the depth needed for proper base installation. For tarmac driveways, this typically means:

- Excavation to 200-250mm depth - Removing existing materials and topsoil

- Type 1 MOT aggregate installation - Laid in 100mm layers and compacted between each layer

- Edge restraints - Installing kerbs or edging to contain the tarmac

- Drainage provisions - Adding channel drains or soakaways if required

The base typically takes 2-3 days to install properly. Rushing this stage compromises the entire driveway, so we don't cut corners on compaction or layer thickness.

Tarmac Surface Application

Tarmac arrives hot (typically 150-160°C) and needs laying immediately. The material comes in two layers for most driveways:

Binder Course (Base Layer)

- Thickness: 50-60mm

- Larger aggregate stones (up to 20mm)

- Provides structural strength

- Gets laid first and compacted with a heavy roller

Wearing Course (Top Layer)

- Thickness: 25-30mm

- Finer aggregates (6-10mm)

- Creates the smooth finished surface

- Applied after binder course has cooled slightly

The hot material gets spread across the prepared base, then compacted using a vibrating roller. This compaction is what gives tarmac its strength and smooth finish - hand-tamping doesn't achieve the same results.

Cooling & Curing Time

Fresh tarmac needs time to cool and set properly. You can typically walk on it within a few hours, but vehicle access requires more caution:

- Light vehicles (cars): 24 hours after installation

- Heavy vehicles: 48-72 hours recommended

- Full cure: 4-6 weeks for complete hardening

During the first few weeks, avoid sharp turns or heavy braking on the surface. The tarmac continues hardening during this period, and concentrated forces can mark the surface whilst it's still relatively soft.

Edging Options

Tarmac needs edge restraints to prevent the material spreading or crumbling at boundaries. Common options include:

Block Paving Edging The most popular choice - a row of block pavers installed around the perimeter and at the driveway entrance. This provides a neat, defined edge and adds visual interest. We typically install 2-3 rows of blocks at the entrance where vehicle wheels turn onto the drive.

Concrete Edging A concrete haunch poured along the edges provides a solid restraint. This gets hidden by soil or turf, so it's invisible but effective. Suitable if you want a seamless appearance without visible edging.

Timber Edging Less common but viable for certain situations. Treated timber boards held by stakes provide temporary or semi-permanent edge restraint. This typically needs replacing every 5-10 years as the wood deteriorates.

Tarmac Driveway Installer near me

If you're looking for a tarmac driveway installer near me in Coventry then please get in touch today

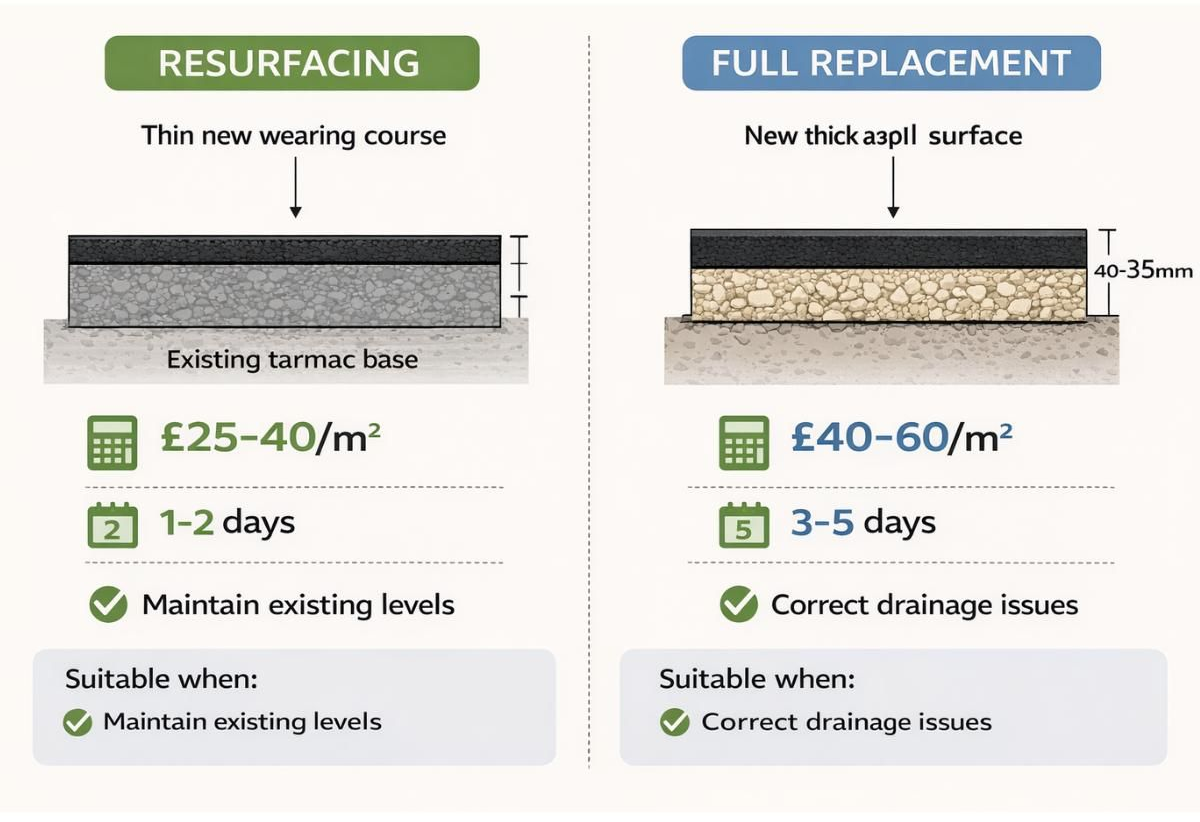

Tarmac Driveway Resurfacing Coventry

Resurfacing offers a cost-effective way to refresh an existing tarmac driveway without full replacement. Not every drive is suitable for resurfacing - the existing base must be sound - but when viable, it saves significant money and disruption.

When Resurfacing is Suitable

We can resurface your tarmac driveway if:

- The existing base is structurally sound with no major cracks or subsidence

- Surface deterioration is limited to the wearing course (top layer)

- Drainage is adequate and doesn't need modification

- The existing levels work with your property boundaries and drainage

Resurfacing involves applying a new wearing course over the existing surface. This gives you what looks like a completely new driveway at roughly half the cost of full replacement.

When Full Replacement is Necessary

Some driveways have deteriorated beyond resurfacing. We recommend full replacement if:

Base Failure If the base has failed - evidenced by significant cracks, dips, or areas where the surface has broken up completely - resurfacing won't solve the underlying problem. The new surface will simply fail in the same places.

Drainage Issues If water pools on your driveway or drainage has never worked properly, resurfacing doesn't address this. Full replacement allows us to correct the gradient and install proper drainage solutions.

Height Restrictions Resurfacing adds 30-40mm to your driveway height. If this creates issues with garage access, property thresholds, or drainage, we need to remove some of the existing material first or opt for full replacement.

The Resurfacing Process

Resurfacing is quicker than full installation - typically 1-2 days for most domestic driveways:

- Surface preparation - Cleaning the existing surface, removing loose material, and treating any oil stains

- Tack coat application - A bitumen emulsion that bonds the new surface to the old

- New wearing course - 25-30mm of fresh tarmac or asphalt applied across the entire surface

- Compaction and finishing - Roller compaction creates the smooth finished surface

The result looks identical to a newly installed driveway at a fraction of the cost. With proper maintenance, a resurfaced drive should last another 10-15 years.

Colour Changes During Resurfacing

Resurfacing provides an opportunity to change your driveway colour. If you've got standard black tarmac but fancy red, buff, or grey, resurfacing is the time to make that change.

The colour sits in the wearing course (the top layer we're replacing), so you get complete colour coverage. There's no compromise on appearance compared to installing the coloured material from scratch.

Tarmac Driveway Maintenance Guide

Proper maintenance extends your tarmac driveway's life and keeps it looking presentable. The effort required is minimal compared to block paving or natural stone, but neglecting basic care leads to premature deterioration.

Regular Cleaning

Weekly/Monthly Maintenance

- Sweep with a stiff broom to remove dirt, leaves, and debris

- Clear any vegetation growing at edges before it establishes

- Remove oil drips promptly using absorbent materials

Annual Deep Cleaning

- Pressure wash on a low-medium setting (too high dislodges surface material)

- Use a suitable tarmac cleaner for stubborn stains or organic growth

- Treat any moss or algae with appropriate biocides

Be cautious with pressure washers - the high-pressure jet can dislodge aggregate stones, particularly on older tarmac surfaces. Start at low pressure and only increase if necessary.

Sealing Your Tarmac Driveway

Tarmac sealant protects the surface and extends its life considerably. We recommend sealing every 3-5 years, though this depends on usage and exposure.

Benefits of Sealing:

- Protects against UV degradation that causes fading and brittleness

- Prevents water penetration that leads to frost damage

- Restores the deep black appearance that fades over time

- Makes the surface easier to clean and maintain

- Reduces fuel and oil penetration

When to Seal:

- Wait at least 6 months after installation before first sealing

- Seal when the surface looks faded or dry

- Re-seal every 3-5 years depending on wear

- Choose dry weather with temperatures above 10°C

Sealant application is straightforward - the surface gets cleaned thoroughly, allowed to dry, then the sealant applied with a brush or squeegee. Most products need 24 hours to dry before the driveway can be used.

Repairing Minor Damage

Small problems caught early prevent major repairs later.

Surface Cracks Hairline cracks are normal as tarmac ages. Fill them with crack filler before water penetrates and causes the crack to widen. This is a simple DIY job with products available from builders merchants.

Potholes If surface material dislodges, creating small depressions, repair them promptly. Cold-lay tarmac repair products work for small patches - you add the material, compact it down, and it sets over time.

For larger areas or multiple potholes, professional repair provides better results. We can cut out the damaged section and install proper hot-lay tarmac that bonds correctly to the surrounding surface.

Edge Crumbling Edges are vulnerable points, particularly if edging restraints are inadequate. If edges start crumbling, we can install or reinforce edge restraints and repair the affected tarmac.

What Damages Tarmac Surfaces

Understanding what harms tarmac helps you avoid problems:

- Fuel and oil spills - Though modern asphalt resists these better than old tarmac, prolonged exposure still causes degradation

- Sharp concentrated loads - Kickstands on motorcycles or narrow feet on heavy equipment can indent fresh tarmac

- Aggressive chemicals - Some de-icing salts and cleaning products damage the bitumen binder

- Neglected vegetation - Weeds growing at edges work under the tarmac and lift it

- Heavy impacts - Dropping heavy objects or aggressive digging near the surface causes damage

Tarmac vs Other Driveway Materials

Choosing between tarmac and alternative materials depends on your priorities, budget, and property requirements. Here's how tarmac compares to the main alternatives available in Coventry.

Tarmac vs Resin Driveways

Cost Comparison Tarmac costs £40-£60 per m² whilst resin bound surfaces cost £80-£100 per m². For a 50m² driveway, that's a £2,000-£3,000 difference - significant for most budgets.

Maintenance Resin requires less maintenance - the sealed surface resists weeds naturally and rarely needs treatment. Tarmac needs periodic sealing and occasional weed treatment at edges.

Appearance Resin offers more design flexibility with various aggregate colours and decorative options. Tarmac is more utilitarian, though coloured options provide some variety.

Longevity Resin lasts 15-20 years with minimal maintenance. Tarmac lasts 15-20 years but needs resurfacing after 10-15 years to maintain appearance and performance.

Verdict: If budget allows and you want low maintenance with contemporary appearance, resin wins. If cost matters and you don't mind basic upkeep, tarmac provides excellent value.

Tarmac vs Block Paving

Cost Comparison Block paving costs £60-£85 per m², sitting between tarmac and resin. The price varies significantly based on block quality and pattern complexity.

Installation Time Tarmac installs faster - 3-5 days typical. Block paving takes 5-7 days due to the labour-intensive laying process.

Repairability Block paving wins here - individual damaged blocks can be replaced without disturbing surrounding areas. Tarmac repairs are more visible and harder to blend seamlessly.

Design Options Block paving offers far more design flexibility - patterns, colours, borders, and custom layouts. Tarmac is more limited to colour choices and simple shapes.

Maintenance Tarmac needs less frequent maintenance. Block paving requires joint re-sanding every 2-3 years and weed treatment between blocks.

Verdict: Block paving suits homeowners who want design flexibility and don't mind maintenance. Tarmac suits those prioritizing cost and simplicity.

Tarmac vs Concrete

Cost Comparison Basic concrete costs £45-£65 per m², similar to tarmac. Imprinted concrete costs £75-£95 per m², significantly more.

Appearance Standard concrete is plain grey. Tarmac's black or charcoal appearance is more refined. Imprinted concrete offers decorative patterns but at premium cost.

Curing Time Tarmac can take light traffic within 24 hours. Concrete needs 7-10 days before vehicle use - a significant practical difference.

Heavy Load Capacity Concrete handles heavy vehicles better than tarmac. For regular commercial vehicle use or heavy equipment, concrete is superior.

Maintenance Both require periodic sealing. Concrete shows stains more obviously on its lighter surface. Tarmac's dark colour hides minor marks better.

Verdict: For standard domestic use, tarmac is more practical and quicker to install. For heavy commercial use, concrete's superior load-bearing justifies the longer wait.

Tarmac vs Gravel

Cost Comparison Gravel is cheaper initially at £25-£40 per m² installed, but ongoing maintenance costs accumulate over time.

Maintenance Gravel requires frequent attention - raking, topping up displaced stones, weed control, and edge maintenance. Tarmac needs far less ongoing work.

Practicality Tarmac provides a solid, stable surface. Gravel shifts under vehicles and can be tracked into properties on shoes and tyres.

Permeable Drainage Gravel is fully permeable, meeting drainage regulations without additional infrastructure. Standard tarmac requires drainage solutions.

Security Gravel makes noise when vehicles or people walk on it - some homeowners value this as a security feature. Tarmac is silent.

Verdict: Gravel suits those wanting permeable surfacing on tight budgets who don't mind ongoing maintenance. Tarmac provides a more permanent, practical solution.

Asphalt Driveway

If you're looking for a new asphalt driveway in Coventry then please get in touch today

Choosing the Right Tarmac Contractor in Coventry

The quality of installation matters as much as the material choice. A properly installed tarmac driveway lasts decades, whilst poor installation leads to problems within years.

What to Look For

Groundwork Experience Tarmac installation relies heavily on proper base preparation. Contractors who primarily work on surfacing but lack groundwork experience may produce a nice-looking surface over an inadequate base. Ask about their groundwork background, not just their surfacing experience.

Hot-Lay vs Cold-Lay Materials Professional installations use hot-lay tarmac delivered from an asphalt plant. This provides superior compaction and longevity. Some contractors use cold-lay materials (tarmac in bags) for entire driveways - this is only suitable for small repairs, not full installations.

Equipment Proper tarmac installation requires specific equipment - vibrating rollers for compaction, lorries for hot material delivery, and heating equipment. Contractors without this equipment cannot install tarmac to professional standards.

Guarantees We provide 10-year guarantees on workmanship and installation. Be wary of contractors offering no guarantee or very short guarantee periods - this suggests they're not confident in their work quality.

Questions to Ask Contractors

Before committing to any contractor, ask:

- What thickness base will you install? - Should be minimum 150mm for driveways

- What tarmac thickness? - Should be minimum 75-80mm total (binder + wearing course)

- Do you use hot-lay or cold-lay materials? - Hot-lay is necessary for quality installations

- What edge restraints will you install? - Tarmac needs proper edge support

- What guarantee do you provide? - Should cover workmanship for at least 5 years

- How will you handle drainage? - Should have clear plan for water management

Red Flags to Avoid

Unusually Low Quotes If a quote seems significantly lower than others, there's usually a reason. Common cost-cutting includes inadequate base thickness, thin tarmac layers, or using cold-lay materials throughout.

Pressure to Decide Immediately Legitimate contractors don't pressure you to sign on the spot. Be suspicious of "special offers ending today" or aggressive sales tactics.

Cash-Only Deals Whilst many legitimate contractors offer cash discounts, be wary of those who only accept cash or want full payment upfront. This creates no paper trail if problems arise.

Online Presence Professional contractors have verifiable business premises and contact details. Mobile-only traders with no fixed address are difficult to contact if problems develop later.

Get Your Tarmac Driveway Quote

We provide no-obligation quotes for all tarmac driveway projects across Coventry. Whether you're installing a new driveway, resurfacing an existing one, or exploring your options, we're happy to visit your property and provide honest advice.

Our service includes:

- A site survey and consultation

- Detailed written quotation

- Advice on resurfacing vs full replacement

- Drainage assessment and recommendations

- 10-year workmanship guarantee

Call us on 0247 542 6111 to arrange your free quote, or use the form at the top of this page to send us your measurements and photos for an initial assessment.

We typically respond to enquiries within 24 hours on weekdays and can usually arrange site visits within 3-5 days.

Need help?

Frequently Asked Tarmac Driveway Questions

Areas Covered by Driveways Coventry:

Tarmac Driveways Binley Woods , Tarmac Driveways Baginton, Tarmac Driveways Balsall Common, Tarmac Driveways Ryton-on-Dunsmore, Tarmac Driveways Kenilworth, Tarmac Driveways Allesley, Tarmac Driveways Keresley End, Tarmac Driveways Bedworth, Tarmac Driveways Leamington Spa, Tarmac Driveways Warwick, Tarmac Driveways Rugby